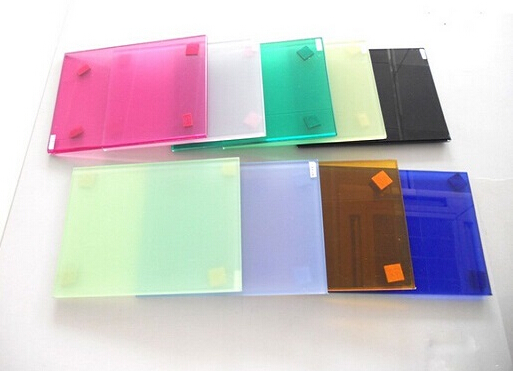

Half tempered glass, also known as heat strengthened glass. Half tempered glass is a type of glass that falls between ordinary flat glass and tempered glass. It combines some of the advantages of tempered glass, such as higher strength than ordinary float glass, which is twice that of ordinary float glass. At the same time, it avoids the unsatisfactory weaknesses of tempered glass, such as poor flatness, easy self explosion, and overall crushing once damaged. When semi tempered glass is damaged, it cracks radially along the crack source in a radial pattern, and generally there is no tangential crack propagation, so it can still maintain its overall integrity after damage.

Purpose:

Half tempered glass is suitable for curtain walls and exterior windows in buildings, and can be made into tempered coated glass with better image distortion than tempered glass.

The Regulations on the Management of Building Safety Glass clearly state that 'single piece semi tempered glass (heat strengthened glass) does not belong to safety glass', because once it breaks, it will form large fragments and radial cracks. Although most fragments do not have sharp corners, they can still harm people and cannot be used for skylights and situations where human impact may occur.

Difference

Difference from tempered glass

Half tempered glass is an annealed glass that undergoes high temperature and quenching, resulting in a compressive stress of less than 69 MPa on the surface, which increases the mechanical strength of the glass several times. The surface stress of semi tempered glass is 24-69Mpa. After being broken, it is the same as ordinary glass, and the product feature is that the strength of semi tempered glass is more than twice that of annealed glass. Safety: When broken, the fragments are radiating and each fragment extends to the edge, making it difficult to fall off and relatively safe, but it does not belong to safety glass. Deflection: The deflection of semi tempered glass is smaller than that of tempered glass and larger than that of annealed glass. Thermal stability: The thermal stability is also significantly better than annealed glass, and ordinary glass can withstand a temperature difference of about 75 ° C after semi tempered treatment. Half tempered glass will not self destruct.

Tempered glass is annealed glass that undergoes high temperature and quenching, resulting in strong compressive stress on the surface, which increases the mechanical strength of the glass several times. The surface stress of tempered glass is 69-168Mpa. Its characteristic is that it breaks into small blunt angled particles, which will not cause significant harm to the human body. The strength is four times or more that of ordinary glass. It has good thermal stability and can withstand a temperature difference of about 180 ° C after ordinary glass tempering treatment. The disadvantage of tempered glass is that it is prone to self explosion

Technical standards

The surface compressive stress of semi tempered glass is between 24MPa and 52MPa, while the surface compressive stress of tempered glass should be greater than 69MPa. The production process of semi tempered glass is the same as that of tempered glass, except for the difference in air pressure at the quenching station, and the cooling energy is lower than that of tempered glass.